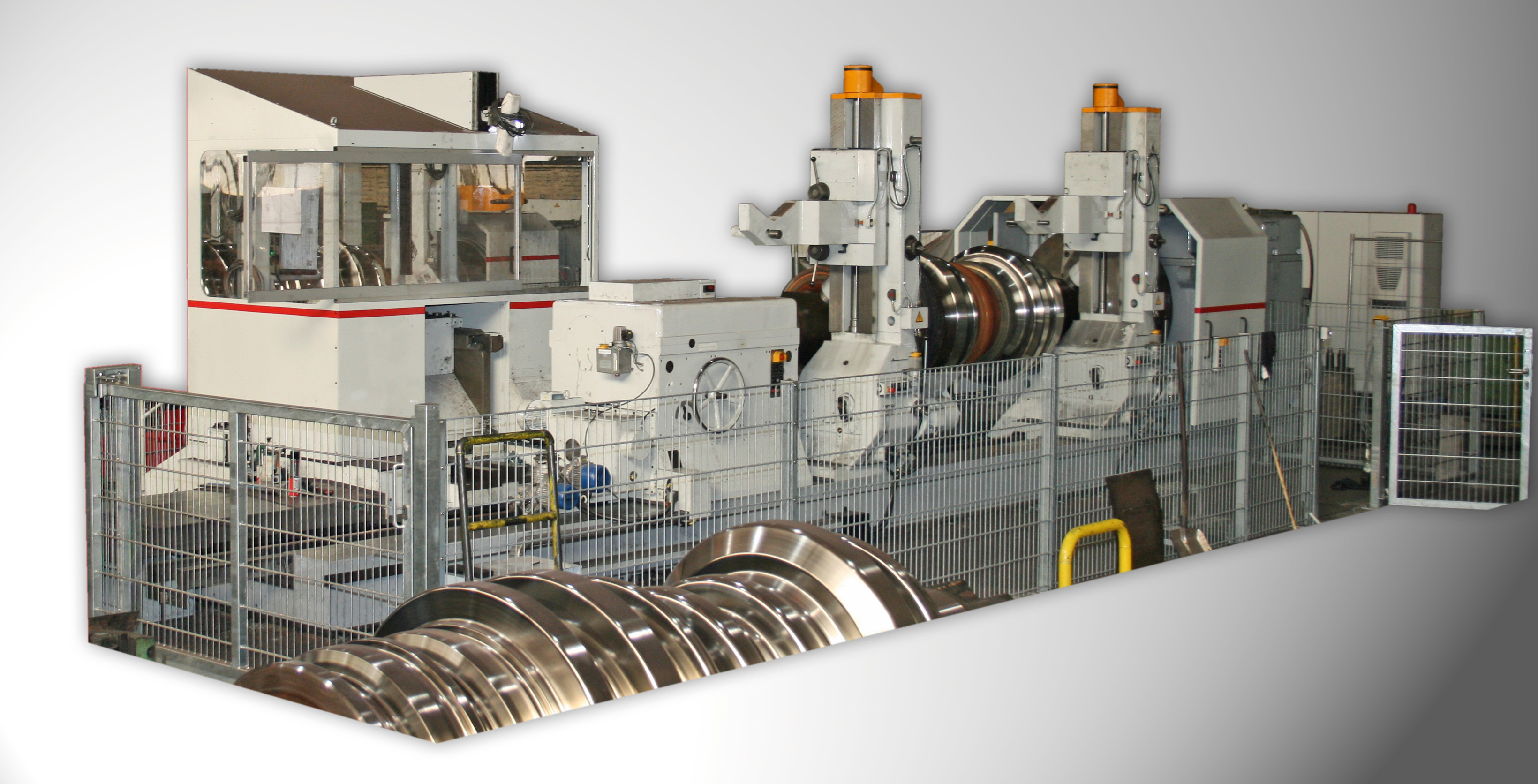

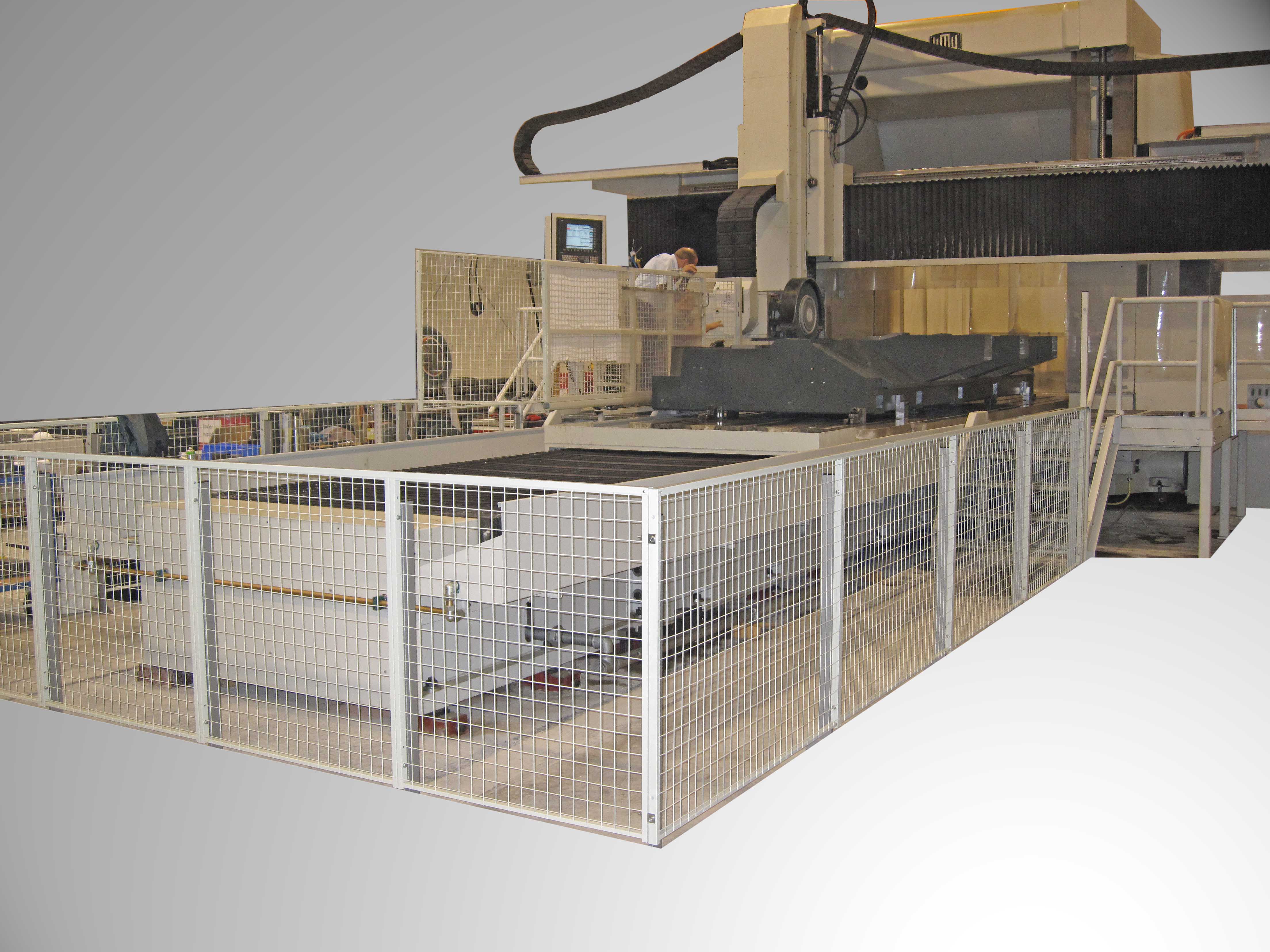

Machine safety

Services of HELLWIG Electrical Engineering – SAFETY TEST ACCORDING TO DGUV AND VDE

HELLWIG offers extensive support in optimizing and expanding your own machinery. You can rely on:

- On-site consulting to implement the safety requirements in accordance with the Ordinance on Industrial Safety and Health or according to Machinery Directive 2006/42 / EC (CE)

- Advice on hazards such as electrical currents, contact voltage, disconnection times

- Creating a detailed risk assessment

- Development of technical documentation such as an operating manual

- Compliance with legal requirements, Product Safety Act, Industrial Safety and Health, Technical Regulations in Operational Safety, German Social Accident Insurance Rule 3 (BGV A3) and German Social Accident Insurance Note 4 (GUV-V A3)(Electrical installations and equipment)

- Use of grounding systems TN system, TT system, IT system

- Protection against electric shock according to DIN VDE 0100-410: 2007-06

- Testing of facilities DIN VDE 0100-600 2008-6 loop impedance, short-circuit current, FI (RCD) exam, isolation and ground resistance

- Testing of electrical machines according to VDE 0113-1 / A1

- Testing of electrical Devices according to DIN VDE 0701 0702/0751

- Electrical current, voltage and power measurements with non-sinusoidal sizes

HELLWIG is your expert for machine tools: We know exactly where to find risks, and which reasonable measures – instead of taking “exaggerated” precautions – offer themselves.